As the “energy heart” of the drone, the drone battery not only serves as its power source but also directly determines flight duration, stability, payload capacity, and operational safety, making it a critical factor influencing the drone’s overall performance.

Taking care of them isn’t just about saving money—it’s about avoiding mission failures and ensuring consistent performance. Here are the industry-insider tips that actually work:

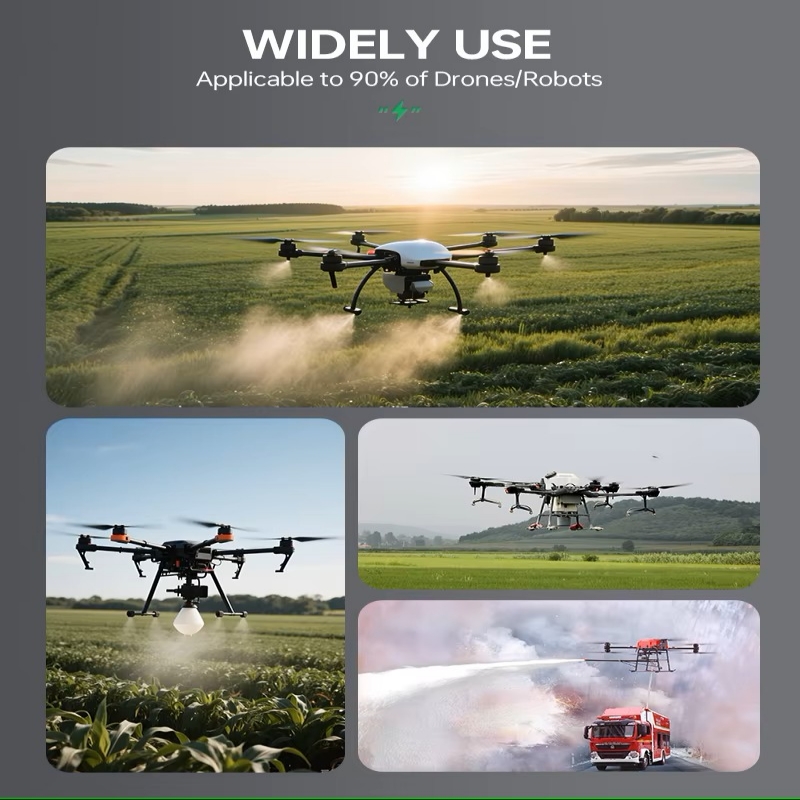

Start with the basics: use the right battery. It sounds simple, but skipping the manufacturer’s recommended battery for a cheaper alternative is a recipe for disaster. Every drone is engineered to work with specific battery types and capacities, and using the wrong one can cause overheating, reduced flight time, or even permanent damage to the drone’s power system.

Storage is make-or-break for battery lifespan. Most operators don’t realize that storing a battery at full charge or near-empty can ruin its cells over time. The sweet spot is 50% charge—enough to keep the cells healthy without stressing them.

Store your batteries in a cool, dry place (between 68°F and 77°F is ideal) away from direct sunlight or extreme temps. A hot car or a freezing garage will degrade the battery’s chemistry fast, so invest in a fire-resistant battery case to keep them safe during storage and transport—they’re cheap insurance against malfunctions.

Avoid overcharging and over-discharging at all costs. Use only the charger recommended by the manufacturer, and never leave a battery charging overnight. Most modern chargers have auto-shutoff, but it’s still smart to monitor them—overcharging causes overheating, which melts internal components and shortens lifespan.

On the flip side, don’t let your battery drain completely during flights; landing when it hits 20% charge (instead of pushing to 0%) will prevent permanent cell damage.

Fly smarter, not harder. GPS-assisted stable flight modes are designed to be energy-efficient—use them instead of manual modes that require constant motor adjustments. Plan your flight path ahead of time to avoid unnecessary detours; a straight line uses way less power than zig-zagging or making frequent turns.

Skip aggressive maneuvers like sudden acceleration or sharp turns—smooth, controlled movements keep the motors from working overtime. And limit hovering: it might seem low-effort, but keeping the drone stationary requires continuous motor power to fight gravity and wind—cutting hover time by just 5 minutes can add 10+ minutes to your total flight.

How do semi-solid drone battery electrolytes reduce interfacial resistance?

- Understanding the key to semi-solid batteries’ lower internal resistance lies in their innovative electrolyte composition, which differs significantly from traditional battery designs. While conventional batteries typically use liquid electrolytes, semi-solid batteries employ gel-like or paste-like electrolytes that offer numerous advantages in reducing internal resistance. This unique semi-solid state maximizes efficiency and extends battery lifespan by minimizing factors that cause energy loss.

- The lower internal resistance of semi-solid batteries stems from a delicate balance between ionic conductivity and electrode contact. While liquid electrolytes generally exhibit high ionic conductivity, their fluid nature can lead to poor electrode contact. Conversely, solid electrolytes provide excellent electrode contact but often struggle with low ionic conductivity.

- In semi-solid state batteries, the gel-like viscosity of the electrolyte promotes a more stable and uniform interface with electrodes. Unlike liquid electrolytes, semi-solid electrolytes ensure superior contact between electrode and electrolyte surfaces. This enhanced contact minimizes the formation of resistance layers, enhances ion transfer, and reduces the battery’s overall internal resistance.

- The semi-solid nature of the electrolyte helps address challenges associated with electrode expansion and contraction during charge and discharge cycles. The gel-like structure provides additional mechanical stability, ensuring electrode materials remain intact and aligned even under varying stresses.