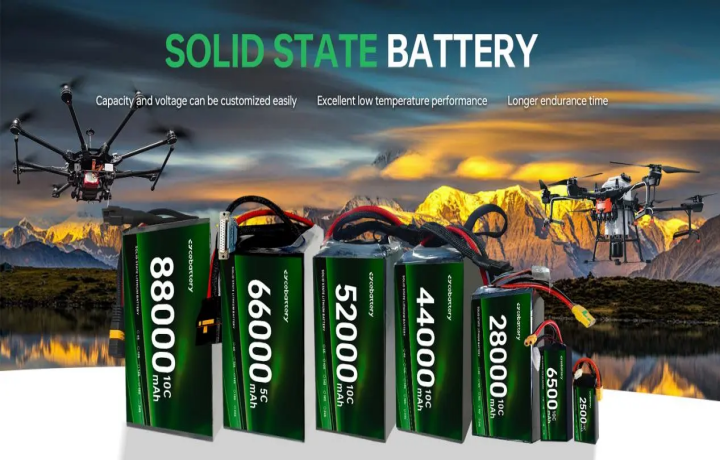

Drone batteries, Lithium-Ion Batteries and Solid-State Batteries: Pioneering a New Era in Low-Altitude Economy.

As drone technology undergoes rapid iteration, the power system—the core “heart” of the drone—is undergoing a revolutionary transformation. From traditional liquid lithium batteries to cutting-edge solid-state batteries, the two technological approaches demonstrate differentiated advantages in different scenarios, jointly driving the large-scale application of drones in agriculture, logistics, emergency rescue, and other fields.

This article will deeply analyze the technical characteristics and scenario adaptability of the two, revealing the future direction of industry development.

Traditional Lithium Batteries: The Foundation and Limitations of Current Applications

Liquid lithium drone batteries have long dominated the drone power market due to their high energy density (250–300 Wh/kg) and mature supply chain. Their lightweight design and cost advantages from mass production make them reliable in consumer drones and short-distance logistics delivery applications.

However, the inherent drawbacks of liquid lithium-ion drone batteries have become industry pain points:

Safety risks: Liquid electrolytes are prone to thermal runaway caused by punctures or overcharging. A 2025 logistics drone crash caused by battery short-circuiting highlighted their vulnerability in high-load scenarios.

Lithium batteries play a crucial role in powering drones, offering high energy density, lightweight design, and reliable performance.

The various types of lithium batteries, including LiPo, Li-ion, LiFePO4, and solid-state batteries, cater to different drone applications and operational requirements. By understanding the characteristics and considerations associated with each type of drone battery, operators can make informed decisions when selecting the right battery for their drones, ultimately enhancing performance, safety, and efficiency in aerial operations.

What Are the Challenges in Developing Solid State Battery Technology?

Despite the promising outlook, several hurdles must be overcome before solid state batteries can achieve widespread commercial adoption:

- Manufacturing Scalability: Current production methods for solid state batteries are complex and expensive, making large-scale manufacturing challenging.

- Interface Stability: Maintaining stable contact between the solid electrolyte and electrodes over numerous charge cycles remains a significant technical challenge.

- Material Selection: Identifying and optimizing materials that offer the right balance of conductivity, stability, and cost-effectiveness is ongoing.

- Low-Temperature Performance: While solid state batteries excel at high temperatures, their performance at lower temperatures still needs improvement.

- Cost Reduction: The current high cost of production limits the commercial viability of solid state batteries, necessitating further research and development to reduce expenses.

Overcoming these challenges requires continued investment in research and development, as well as collaboration between academia, industry, and government entities.

If you’re interested in learning more about semi solid state battery or exploring how this technology can benefit your applications, we invite you to get in touch with our team of experts.

At CEBATTERY, we’re committed to staying at the forefront of battery innovation and providing cutting-edge solutions to meet your energy storage needs.

Contact us at levin@cebattery.com to discuss how semi solid state batteries can revolutionize your power systems and drive your projects forward. Our knowledgeable staff is ready to answer your questions and help you find the perfect energy storage solution for your unique requirements.